GE IS210AEBIH1BED General Electric Speedtronic Mark V

GE IS210AEBIH1BED is an important industrial automation module produced by General Electric, mainly used for the management of heavy steam and gas turbine systems. This product belongs to the Speedtronic Mark VI series and represents General Electric's latest technology and proprietary software integration in turbine management systems.

Product Introduction

Systems are widely used for the management and control of gas turbines. The Speedtronic Mark V system is an integrated control system designed to optimize the performance and reliability of gas turbines in a variety of industries such as power generation, oil and gas production, and mechanical drive applications.

The IS210AEBIH1BED, like other components within the Speedtronic Mark V system, plays a vital role in ensuring these turbines operate efficiently. While specific details about this particular part may vary depending on its exact function within the system, such components generally involve aspects such as signal processing, communications, or power management within the control system.

Key features and considerations of the GE Speedtronic Mark V system, which also apply to components such as the IS210AEBIH1BED, include:

Reliability and durability: Designed to withstand the harsh operating conditions typical of industrial environments.

Advanced control capabilities: Provides sophisticated algorithms for optimizing turbine performance, including load control, speed control, and protection functions.

Scalability and upgradeability: The system is modular in design and can be easily upgraded and expanded to meet changing needs.

Integration capabilities: Can be integrated with other systems and technologies to increase operational efficiency and flexibility.

Comprehensive Diagnostics and Monitoring: Provides detailed diagnostics and monitoring capabilities to ensure optimal performance and minimize downtime.

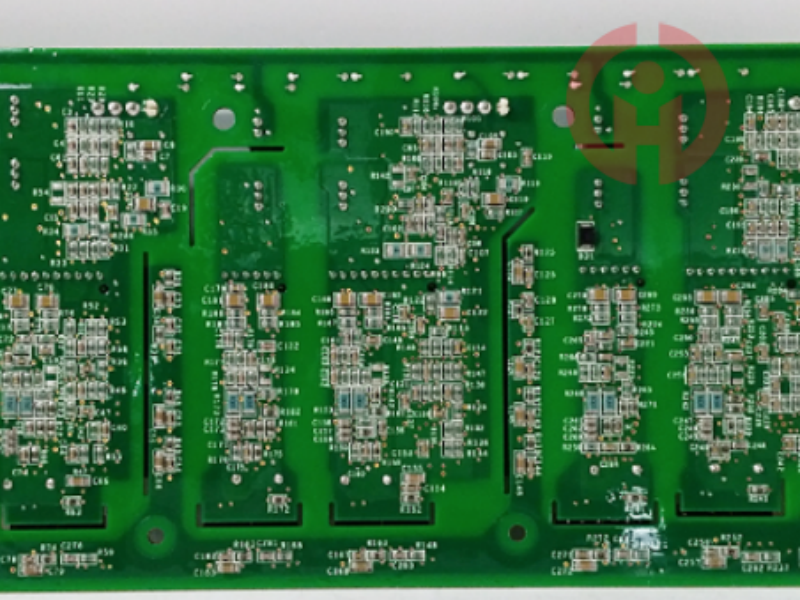

The GE Fanuc IS210AEBIH1BED is an input/output (I/O) module designed for industrial automation systems. It is part of the GE Fanuc family of automation components and integrates with a programmable logic controller (PLC) to connect a variety of sensors, actuators, and other devices.

Input/Output Interface:

Provides connectivity between the PLC and external devices.

Provides digital inputs for reading sensor signals and digital outputs for controlling actuators.

Signal Conditioning:

Contains circuitry that conditions sensor signals.

May provide functions such as scaling, filtering, or converting analog signals to digital.

Communication:

Communicates with the PLC using a specific protocol.

Possible protocols include serial, Ethernet, or other industrial networks.

Configuration:

Configurable through the PLC's programming software.

Allows customization to meet specific application requirements.

I think you'll find our product offers great value for money!

It's my pleasure to introduce our latest product, which will be a great addition to your current offerings!

We're thrilled to introduce you to our latest product, which we believe will meet your needs perfectly!

We believe this product can help to expand your market share. We look forward to the opportunity to work with you!

We sincerely welcome your calls and consultations and provide you with quality service 24 hours a day!

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

.Technical Team Service Hotline:wujinghan102@gmail.com +86 13376990653

csyili980622@gmail.com +86 13306931261