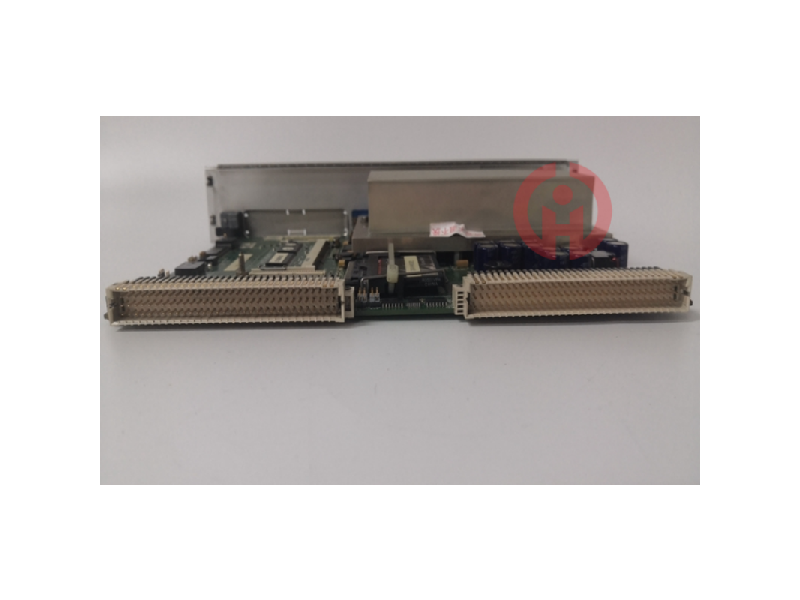

GE IS215UCVFH2BB | VMIVME-7650-83H | 350-007650-83H C | Mark VI Card

GE IS215UCVFH2BB VMIVME-7650-83H 350-007650-83H C is a control system card produced by General Electric (GE), mainly used for controlling and monitoring industrial equipment and systems, especially for gas turbine control.

Related products

Product Introduction

IS215UCVFH2BB VMIVME-7650-83H 350-007650-83H C Tension controller High reliability, strong anti-interference ability

High reliability is the key function of electrical control equipment. PLC adopts modern large-scale integrated circuit technology, adopts strict production process, and the internal circuit adopts the most advanced anti-interference technology, which has high reliability. For example, the F series PLC produced by Mitsubishi has an average trouble-free time of up to 300,000 hours. Some PLCs using redundant CPUs have an average trouble-free working time that is even longer. From the perspective of the PLC's external circuit, the use of PLC to form a control system has reduced the number of electrical wiring and switch contacts to hundreds or even thousands of points compared to the relay contactor system of the same size, and the number of faults has been greatly reduced. In addition, PLC has a hardware fault self-detection function, and can issue an alarm message in time when a fault occurs. In the application software, users can also program the fault self-diagnosis program of peripheral equipment, so that the circuits and equipment in the system other than PLC can also obtain fault self-diagnosis protection. In this way, it is not surprising that the whole system has extremely high reliability.

Complete supporting facilities, perfect functions, strong applicability

After development, a series of products of various sizes, large, medium and small, have been formed. It can be used in industrial control occasions of various sizes. In addition to the logic processing function, most modern PLCs have perfect data computing capabilities and can be used in various digital control fields. In recent years, many PLC functional units have appeared, making PLC penetrate into various industrial controls such as position control, temperature control, CNC, etc. With the enhancement of PLC communication capabilities and the development of human-machine interface skills, it has become very simple to use PLC to form various control systems.

Functional features

Gas turbine control: These cards are usually used to monitor and control the operation of gas turbines, including controlling fuel supply, adjusting generator load and monitoring performance parameters.

Card interface: They are usually connected to the control system to communicate and exchange data with other control devices.

High availability: These cards are usually designed with high availability to ensure the continuous operation of gas turbines, including redundancy and fault recovery functions.

Communication interface: usually supports multiple communication interfaces to exchange data with other control systems or monitoring systems, realize system integration and remote monitoring.

Data processing: these cards can usually process a large amount of data, including performance parameters, sensor data and control signals.

IS215UCVFH2BB VMIVME-7650-83H 350-007650-83H C Tension controller High reliability and strong anti-interference ability

High reliability is a key function of electrical control equipment. PLC adopts modern large-scale integrated circuit skills and strict production technology. The internal circuit adopts advanced anti-interference technology and has high reliability. For example, the F series PLC produced by Mitsubishi has an average failure-free time of up to 300,000 hours. Some PLCs using redundant CPUs have a longer average failure-free working time. From the external circuit of the PLC, the control system is composed of PLC. Compared with the relay contactor system of the same scale, the electrical wiring and switch contacts are reduced by hundreds or even thousands of times, and the problems are greatly reduced. In addition, the PLC has a hardware defect self-detection function, which can promptly announce alarm information when defects occur. When using the software, users can also program the fault self-diagnosis program of peripheral devices, so that the circuits and equipment in the system other than PLC can also obtain fault self-diagnosis and maintenance. In this way, it is not surprising that the whole system has high reliability.

Complete supporting facilities, perfect functions and strong applicability

Up to now, large, medium and small series of products have been formed. It can be used for industrial control occasions of various sizes. In addition to the logic processing function, most modern PLCs have perfect data computing capabilities and can be used in various digital control fields. In recent years, many functional units of PLC have appeared, which makes PLC immersed in various industrial controls such as position control, temperature control, CNC, etc. With the enhancement of PLC communication capabilities and the development of human-machine interface skills, it has become very simple to use PLC to form various control systems.

The output current (drive capacity) of the output module is greater than the rated current of the load. Users should select the output current of the module according to the size of the actual load current. If the actual load current is large, the output module cannot be driven directly, and the intermediate amplification link can be added.

The number of output points connected at the same time

When selecting an output module, the number of output points that can be connected at the same time should also be considered. The cumulative current value of the outputs connected at the same time is less than the current value allowed to pass through the common terminal. For example, for an 8-point output module of 220V/2A, each output point can pass 2A of current, but the current allowed to pass through the output common terminal is not 16A (8X2) and is usually much smaller than this value. Generally speaking, the number of points connected at the same time should not exceed 60% of the number of output points at the same common terminal.

Relationship between the output maximum load current and factors such as load type and ambient temperature

Table 1 shows the output technical indicators of the FX series PLC, which are closely related to different loads. In addition, the maximum output current of the bidirectional thyristor will decrease with the increase of ambient temperature, which should also be noted in actual use.

I think you'll find our product offers great value for money!

It's my pleasure to introduce our latest product, which will be a great addition to your current offerings!

We're thrilled to introduce you to our latest product, which we believe will meet your needs perfectly!

We believe this product can help to expand your market share. We look forward to the opportunity to work with you!

We sincerely welcome your calls and consultations and provide you with quality service 24 hours a day!

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

.Technical Team Service Hotline:wujinghan102@gmail.com +86 13376990653

csyili980622@gmail.com +86 13306931261