GE IS200TBAIH1CED MARK VI Terminal Board

GE IS200TBAIH1CED MARK VI Terminal Board has become an important component in the field of industrial automation with its high performance, reliable electrical characteristics and wide application areas. Whether in terms of physical design or electrical performance, it meets the needs of modern industry for efficient and stable equipment.

Product Introduction

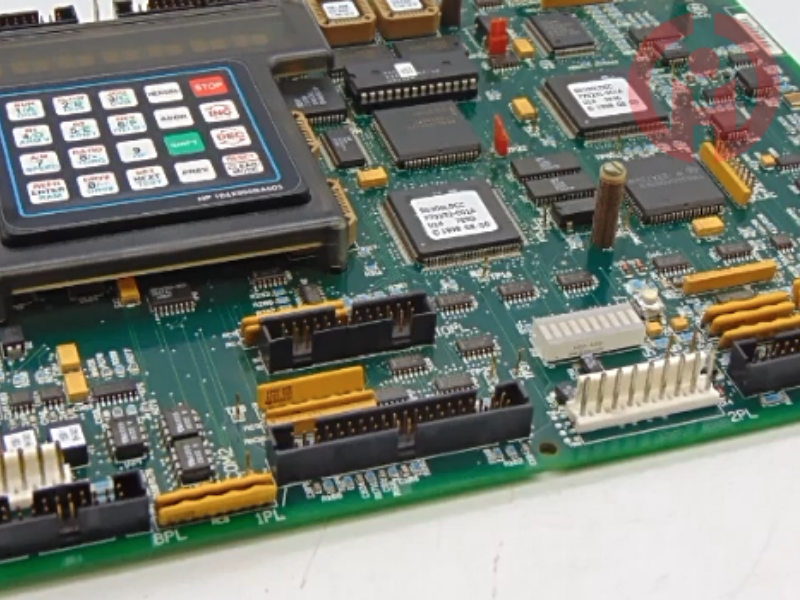

General Electric IS200TBAIH1CEDGE The IS200TBAIH1CED is an analog I/O terminal board developed by General Electric for the Mark VIe control system. It is designed to process analog signals and integrate up to 10 channels. The IS200TBAIH1CED is primarily used in industrial control systems, especially those that employ the GE Speedtronic Mark VI platform. It is suitable for applications that require high-speed network I/O in various configurations.

General Electric IS200TBAIH1CEDGE The IS200TBAIH1CED is an analog I/O terminal board developed by General Electric for the Mark VIe control system. It is designed to process analog signals and integrate up to 10 channels. The IS200TBAIH1CED is primarily used in industrial control systems, especially those that employ the GE Speedtronic Mark VI platform. It is suitable for applications that require high-speed network I/O in various configurations.

Main Features:

Analog I/O Function:

Processes analog signals

Integrates up to 10 channels

Compatibility:

Designed for GE Speedtronic Mark VI Series Systems

Provides high-speed network I/O for simplex, duplex and triplex redundant systems.

Connectivity:

Terminates to external I/O connections

A removable connector on one section of the terminal block.

Product Features:

Isolated analog inputs

Digital inputs and outputs

Compatibility with a wide range of transmitters

Versatility in control systems.

Main Features:

Analog I/O Function: Processes analog signals

Integrates up to 10 channels

Compatibility:

Designed for GE Speedtronic Mark VI Series Systems

Provides high-speed network I/O for simplex, duplex and triplex redundant systems.

Connectivity:

Terminates to external I/O connections

A removable connector on one section of the terminal block.

IS200TBAIH1CED is an analog I/O terminal board developed by GE. It is part of the Mark VIe control system. The Analog Input/Output (TBAI) Terminal Board is a component within a control system that provides a variety of functions and powerful analog signal processing capabilities. It facilitates the integration of analog inputs and supports up to 10 channels. These inputs are designed to accommodate various types of transmitters, including two-wire, three-wire, four-wire, or externally powered sensors. This flexibility allows for seamless integration with different types of sensors and measurement devices.

Features

Analog Output Capability: In addition to analog inputs, it provides two output channels that can be configured to output 0-20 mA or 0-200 mA current signals. This versatility enables precise control and modulation of the output signal to meet specific system requirements.

Noise Suppression Circuitry: To ensure signal integrity and reliability, both input and output channels are equipped with noise suppression circuitry. This feature protects against surges and high-frequency noise, maintaining signal quality and stability even in challenging operating environments.

Connection Options: Designed with three DC-37 pin connectors specifically for connecting to VAICs. For simplex applications, a single connector (JR1) is used, while TMR (Triple Modular Redundancy) applications utilize all three connectors. This setup allows for seamless integration and communication between the TBAI and VAIC, ensuring optimal performance and reliability.

Operation in TMR Applications: In a TMR configuration, the input signals are distributed across three connectors dedicated to R, S, and T control. The board intelligently combines the current outputs from the three connected drives and determines the total current using a measurement shunt. This total current signal is then provided to the VAIC for regulation based on the commanded set point, enabling precise control and synchronization in a redundant system architecture.

Diagnostics

Voltage Drop Monitoring: To monitor output current, the terminal board measures the voltage drop in the circuit using a series resistor. This voltage drop serves as an indicator of the output current level. If the current level is abnormal, the voltage analog input/output card (VAIC) triggers a diagnostic alarm or fault, signaling that there may be a problem with the output.

Connector ID Device: Each cable connector on the terminal board is equipped with an ID device that serves as a unique identifier for the board. This ID device contains critical information, including the serial number, type, revision number, and connector position (JR, JS, JT) of the terminal board. When the VAIC interrogates these ID devices, any discrepancy or mismatch triggers a hardware incompatibility fault.

Fault Detection Mechanism: When an output current anomaly is detected or a hardware incompatibility issue is encountered, the VAIC generates a diagnostic alarm or fault. These fault notifications provide real-time feedback on the health and integrity of the terminal board, enabling the prompt identification and resolution of potential problems.

Integration with Control Systems: Diagnostic information generated by the terminal board is seamlessly integrated into the wider control system. This integration enables operators and maintenance personnel to monitor the status of the terminal board and effectively resolve any detected faults.

Benefits of Powerful Diagnostics: By leveraging advanced diagnostics, the terminal board improves system reliability, minimizes downtime, and simplifies maintenance. Early detection of problems enables proactive troubleshooting and corrective actions, ensuring uninterrupted operation of the control system.

GE Fanuc IS200TBAIH1CED Mark VI The IS200 Analog Terminal Board is an essential component of the Mark VI distributed control system. It provides a reliable interface for connecting analog input signals, enabling accurate measurement and monitoring of process variables.

Wide Input Range: Handles a wide range of analog input signals, including voltage and current, to meet different measurement needs.

High Accuracy: Provides precise and reliable analog measurements for accurate process control and monitoring.

Modular Design: Easily integrates into the Mark VI control system, providing flexible configuration and expansion options.

Applications

Process Control: Monitor and control process variables such as temperature, pressure, flow and level in industries such as chemical, pharmaceutical and power generation.

Data Acquisition: Collect analog data from sensors and field devices for detailed analysis and reporting.

I think you'll find our product offers great value for money!

It's my pleasure to introduce our latest product, which will be a great addition to your current offerings!

We're thrilled to introduce you to our latest product, which we believe will meet your needs perfectly!

We believe this product can help to expand your market share. We look forward to the opportunity to work with you!

We sincerely welcome your calls and consultations and provide you with quality service 24 hours a day!

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

.Technical Team Service Hotline:wujinghan102@gmail.com +86 13376990653

csyili980622@gmail.com +86 13306931261