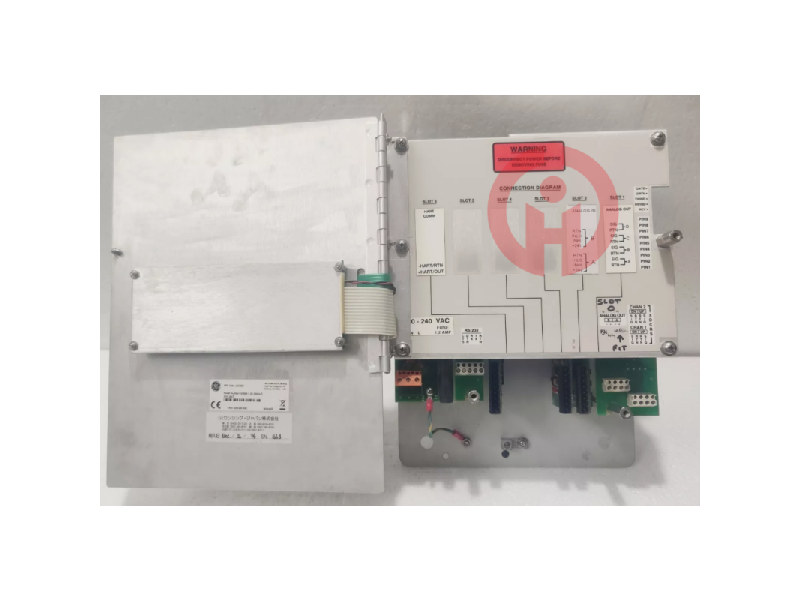

GE GF868-1-2-1-2-1-B-1-4-0-0-0-CC-RPT GF868 Ultrasonic Flare Flowmeters

GE GF868 Ultrasonic Flowmeter is a device designed specifically for measuring the mass flow of flare gas (combustion exhaust gas). The flow meter measures the mass flow of fluid by utilizing the propagation characteristics of ultrasonic waves. It has a variety of models and configurations to meet different industrial application requirements.

Product Introduction

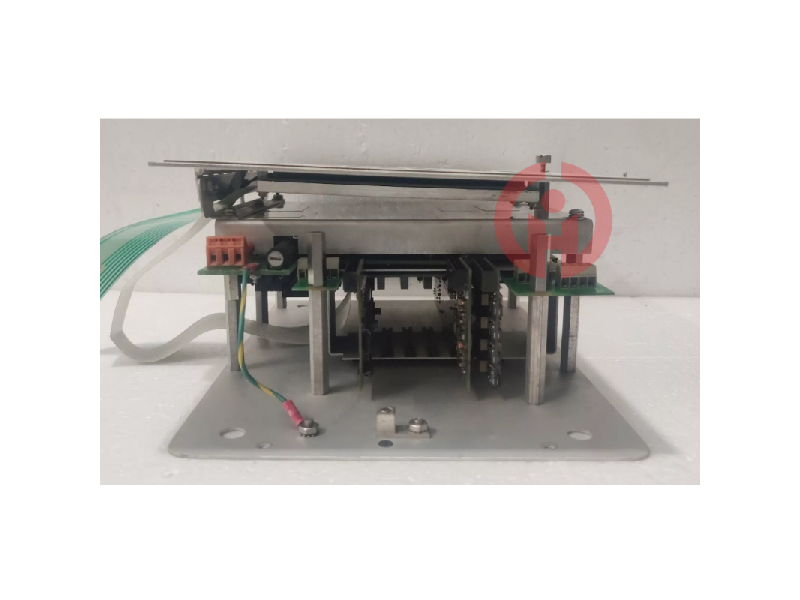

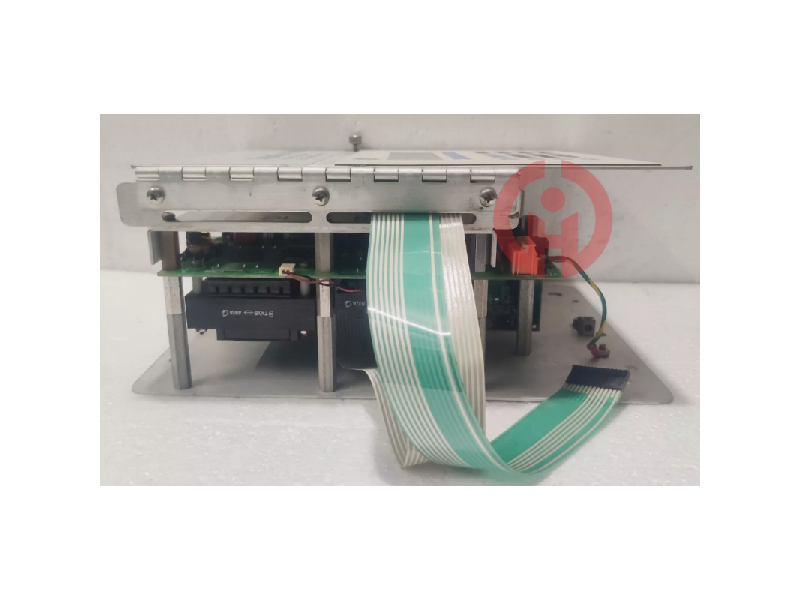

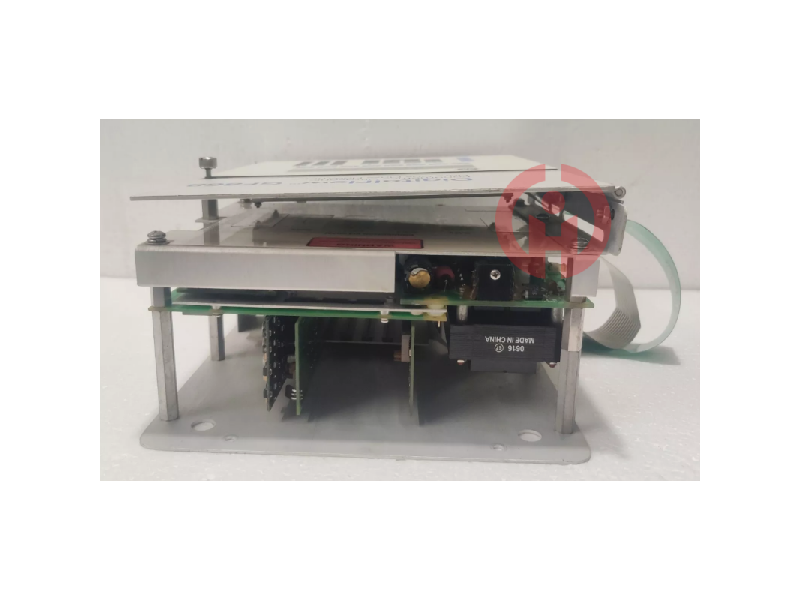

The GE GF868 -1-2-1-2-1-B-1-4-0-0-0-CC-RPT is an ultrasonic flow meter designed for flare gas applications. It is manufactured by General Electric (GE) as part of its Panametrics DigitalFlow series.

Key Features:

Ultrasonic Technology: Uses high-frequency sound waves to measure fluid flow.

Flare Gas Specific: Used to measure molecular weight and mass flow rate of flare gases.

Wide Range Capability: Measures flow rates from 0.1 to 394 ft/sec.

Large Diameter Compatibility: Suitable for stacks up to 120 inches in diameter.

No Moving Parts: Eliminates wear and clogging issues common to other flow measurement methods.

Specifications:

Flow Measurement Range: 0.1 to 394 ft/sec (30.8 to 119.6 m/sec).

Pipe/Stack Size: Up to 120 inches (3047 mm) in diameter.

Working Environment: Able to operate in unsteady flow, pulsating pressure, varying composition and temperature, harsh environments.

Additional Information:

Measurement Method: Utilizes patented correlated transient technology and digital signal processing.

Accuracy: Provides high accuracy without routine maintenance.

Energy Efficiency: Helps improve efficiency in petrochemical plants, refineries and offshore platforms.

Pollution Control Compliance: Assists in complying with pollution control regulations by identifying leak sources in flare systems.

GE GF868-1-2-1-2-1-B-1-4-0-0-0-CC-RPT GF868 Ultrasonic Flare Flow Meter. DigitalFlow GF868 Panametrics Flare Gas Quality Ultrasonic Flow Meter has a wide range of performance, using patented correlated transient technology, digital signal processing and accurate molecular weight calculation. In addition to this, the inherent advantages of ultrasonic flow measurement include high reliability without routine maintenance, high accuracy, fast response and wide range, making it an excellent choice for flare gas applications.

This is an ultrasonic flow meter designed specifically for flare gas applications.

From the model number, it has some custom or specific configurations (such as GF868-1-2-1-2-1-B-1-4-0-0-0-CC-RPT), which can indicate that specific settings or options have been selected for the device.

It is manufactured by General Electric (GE), a well-known brand in the field of industrial measurement equipment.

Ultrasonic flow meters use high-frequency sound waves to measure fluid flow, making them suitable for harsh environments such as flare gas applications.

Flow meters are commonly used in refineries, chemical plants and other industrial facilities where flare gas management is critical.

GE GF868 Flare Gas Ultrasonic Mass Flow Meter

The GF868 flow meter can be used in different application environments, even pulsating gas flow, pressure fluctuations, composition and temperature changes and harsh environments. It is also suitable for a wide flow range of typical flare systems. It can measure flow velocities from 0.1 to 275ft/s (0.03 to 85m/s) in both directions in pipes or stacks with pipe diameters as large as 120in (3 m). There are no moving parts or orifices that can be blocked or worn. The GF868 flowmeter is not affected by the properties of the gas and does not require routine maintenance.

The GF868 flare gas flowmeter can improve the efficiency of petrochemical plants, refineries and offshore platforms. It uses appropriate algorithms to measure the instant molecular weight and mass flow of flare gas. The flowmeter saves energy and reduces product losses by identifying the source of leaks within the flare system. It can also help companies produce more in compliance with pollution control regulations and reduce energy consumption by effectively controlling the amount of steam injection at the top of the flare.

Performance Benefits

· Bidirectional flow range: 0.1 to 275ft/s (0.03 to 85 m/s)

· Measures flow rate, mass and volume flow

· Can measure the instant molecular weight of the gas

· Measurement is not affected by gas composition

· No moving parts; no parts that are blocked or worn

· No routine maintenance required

I think you'll find our product offers great value for money!

It's my pleasure to introduce our latest product, which will be a great addition to your current offerings!

We're thrilled to introduce you to our latest product, which we believe will meet your needs perfectly!

We believe this product can help to expand your market share. We look forward to the opportunity to work with you!

We sincerely welcome your calls and consultations and provide you with quality service 24 hours a day!

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

.Technical Team Service Hotline:wujinghan102@gmail.com +86 13376990653

csyili980622@gmail.com +86 13306931261