Product Introduction

Ethernet KRL communication software package

Functional characteristics

Based on Ethernet communication: relying on mature Ethernet communication technology, high-speed data exchange is achieved to ensure instant and accurate command transmission.

Programming language support: Using KRL (KUKA Robot Language) programming language, developers can flexibly control robot behavior, improve programming efficiency and code maintainability.

Standardized communication: Adopting widely accepted Ethernet standards to ensure standardization and efficiency of cross device communication.

Compatibility and integration friendly: Highly compatible with the KUKA control system, plug and play, users can easily integrate without delving into complex technical details, which can effectively shorten the development cycle.

Application scenarios

In the field of automobile manufacturing, it is used for communication between robots and other equipment on the production line, such as welding equipment, assembly fixtures, etc., to achieve precise welding, assembly and other operations of automobile parts.

Electronic assembly industry: enable robots to work together with surface mount machines, testing equipment, etc. to complete high-speed, high-precision mounting and testing tasks of electronic components.

Logistics sorting scenario: Help robots interact with conveyor lines, scanning equipment, warehousing systems, etc. to achieve rapid sorting and storage of goods.

KUKA. EtherNetIP MS Communication Options

Functional characteristics

EtherNet/IP protocol support: As an open industrial network standard, EtherNet/IP allows real-time control and information integration. This communication option ensures that KUKA robots can leverage this advantage for high-performance data exchange.

Usability Enhancement: Provides detailed installation guidelines and steps for non professional users to quickly get started, reducing integration complexity and improving development efficiency.

High stability and security: The communication mechanism optimized for industrial applications ensures the accuracy of data transmission and the continuous operation of the system.

Application scenarios

In automobile manufacturing, KUKA robots can efficiently collaborate with various equipment on automated production lines based on EtherNet/IP networks, such as precise coordination between robots, material handling equipment, and spraying systems.

In electronic assembly, robots can quickly interact with detection equipment, automated plug-in machines, etc. to achieve high-quality assembly of electronic products.

In precision machining, it helps robots communicate with machine tools, tool management systems, etc., improving machining accuracy and efficiency.

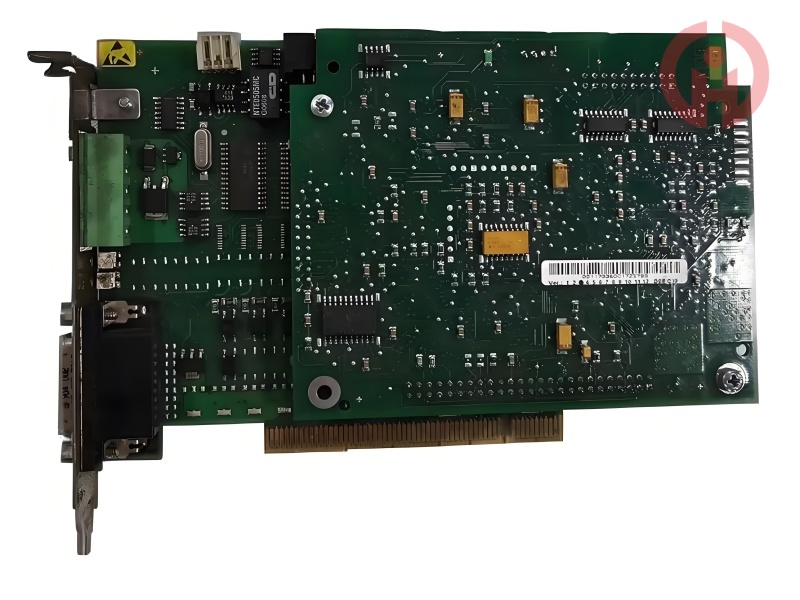

EK series bus coupler module

Functional characteristics

Bus connection function: used to connect different bus systems (such as EtherCAT) and KUKA robot controllers, it is a key component for achieving communication between robots and external devices through a specific bus.

Signal Conversion and Transmission: Able to receive signals from external devices, convert them into a format that the robot controller can understand, and convert the controller's instructions into signals that can be recognized by external devices for output.

Support multiple protocols: Different EK modules may support different communication protocols to meet the needs of different industrial automation systems.

Application scenarios

In an automated production line based on EtherCAT bus, the EK series module can connect KUKA robots with numerous EtherCAT devices, achieving efficient synchronization and collaborative work of the entire production line.

In complex industrial environments that require multiple protocol conversions, selecting EK modules that support corresponding protocols based on actual needs can enable robots to communicate and collaborate with devices of different brands and protocols.

Many products are not yet on the shelves please contact us for more products.

If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will

arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline

csyili980622@gmail.com +86 13306931261

wujinghan102@gmail.com +8613376990653