SIEMENS 6AV6362-3AF00-0BB0 SIMATIC WinCC/DataMonitor

Brand:SIEMENS

Origin: German

SIEMENS 6AV6362-3AF00-0BB0 is a WinCC Server/DataMonitor product. This product is part of the Siemens Automation product family and is primarily used to monitor and control industrial processes.

Product Introduction

1. Product Positioning and Architecture

SIMATIC WinCC/DataMonitor (model 6AV6362-3AF00-0BB0) is an advanced data monitoring and analysis component in the Siemens WinCC software family, designed for data visualization and remote access in industrial scenarios.

-- Core architecture: Developed based on WinCC V7.4 and above, it adopts the browser/server (BS) architecture and supports access to real-time and historical data through Web clients (such as IE, Chrome) or mobile terminals.

-- Data source compatibility: Seamlessly connect to WinCC Runtime, central archive servers and third-party systems (through OPC interfaces), and support real-time data collection from PLCs, sensors and other devices.

2. Core Features

2.1 Data Visualization and Analysis

-- Excel Report Integration: Through the "Excel Workbooks" function, WinCC's real-time process values, historical archive variables and alarm messages can be dynamically displayed directly in Excel tables, supporting data filtering and custom chart generation.

-- Web Publishing and Remote Access: Generate dedicated pages using the Web Center function, integrate trend charts, bar charts, alarm lists and other tools, and support real-time monitoring and data sharing worldwide.

2.2 Advanced Data Management

-- Historical Data Archiving: Support millisecond-level high-speed archiving (up to 1ms), compatible with SQL Server database, can be exported to Excel or cross-platform interaction in XML format.

-- Event Triggering and Automation: Automatically generate reports based on preset conditions (such as time intervals or alarm events) and send them to designated personnel via email.

2.3 Security and Redundancy

-- System Redundancy: Supports dual Web server load balancing to ensure seamless switching and high availability of Web clients.

-- Permission Management: Provides multi-level user permission control (such as operator, administrator), combined with encryption protocol to ensure data security.

3. System Integration and Expansion

3.1 TIA Portal Collaboration: Deeply integrated with Siemens TIA Portal platform to achieve unified engineering configuration of WinCC and PLC (such as S7-1500), reducing the complexity of heterogeneous system development.

3.2 Third-party System Compatibility: Access third-party devices (such as instruments, MES/ERP systems) through OPC UA protocol, support REST API to achieve deep integration with enterprise-level applications.

3.3 Edge Computing Expansion: Compatible with Siemens Industrial Edge Solution, support edge data preprocessing and cloud collaborative analysis.

4. Typical Application Scenarios

4.1 Manufacturing: Real-time monitoring of production line equipment status, analysis of equipment efficiency and optimization of downtime through Web reports.

4.2 Energy Management: Integrate SCADA system, remotely monitor water/electricity/gas consumption data, and generate energy consumption analysis reports.

4.3 Chemical Safety: Real-time collection of reactor temperature and pressure parameters, triggering interlocking protection mechanisms (such as emergency pressure relief), and push alarm information via email.

5. Technical Parameters and Deployment Requirements

Compatible System: Windows 10 IoT Enterprise LTSC (64-bit)

Hardware Recommendations: Processor: Intel Core i5 and above; Memory: 8GB or above; Storage: 256GB SSD or above

Communication Protocol: OPC UA, PROFINET, Ethernet (Gigabit)

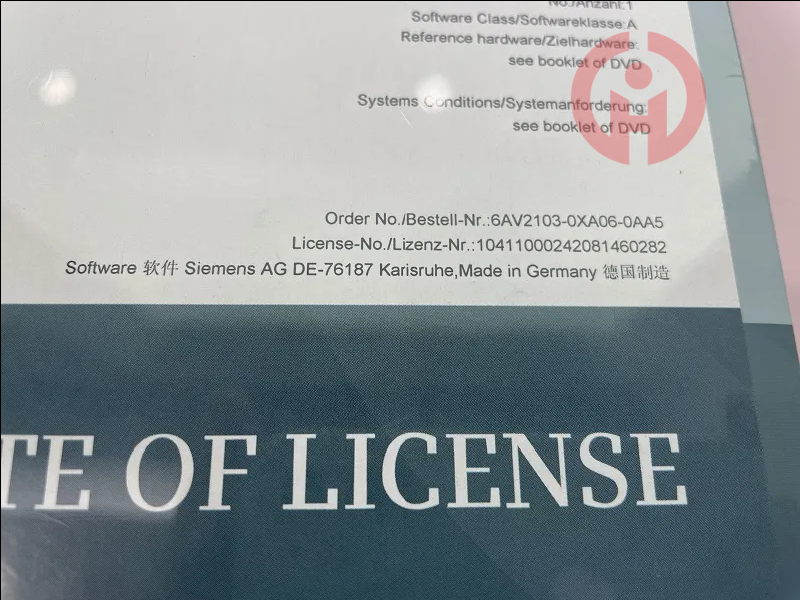

Licensing Mode: A separate license is required, supporting stand-alone or network floating licenses

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline:csyili980622@gmail.com Wechat/SKYPE:+86 13306931261