SIEMENS 6AV6362-1AJ00-0BB0 SIMATIC WinCC/Web Navigator

Brand:SIEMENS

Origin:German

SIEMENS 6AV6362-1AJ00-0BB0 is an important software product of Siemens, specifically, it is a version of WinCC software.WinCC, i.e. “Windows Control Center”, is a powerful software provided by Siemens for industrial automation and monitoring. WinCC, i.e. “Windows Control Center”, is a powerful software provided by Siemens for industrial automation and monitoring, capable of data acquisition, process control, monitoring and visualization, and is one of the core tools for centralized monitoring and management in modern industrial enterprises.

Product Introduction

I. Product Positioning and Core Functions

1.1 Product Positioning

-- As a Web remote monitoring solution in the field of Siemens industrial automation, it supports real-time access to the device status, process data and alarm information of the WinCC system through a browser or mobile terminal, and is suitable for cross-regional, multi-terminal centralized monitoring and maintenance scenarios.

-- Compatible with WinCC V7.4 and above and TIA Portal engineering platform, seamlessly integrated with PLC and SCADA systems, and adapted to the remote management requirements of Industry 4.0 scenarios.

1.2 Core Functions

-- Real-time monitoring and data interaction: Real-time display of device operating status, process values and alarm information through the Web interface, supporting historical data backtracking and trend analysis.

-- Cross-platform access: Supports access through browsers from terminals such as PCs, tablets, and smartphones, without the need to install client software, reducing the complexity of IT deployment.

-- Secure diagnosis and maintenance: Provides WebDiagnoseclient function, allowing service engineers to remotely debug device parameters through encrypted channels to improve maintenance efficiency.

2. Technical parameters and deployment requirements

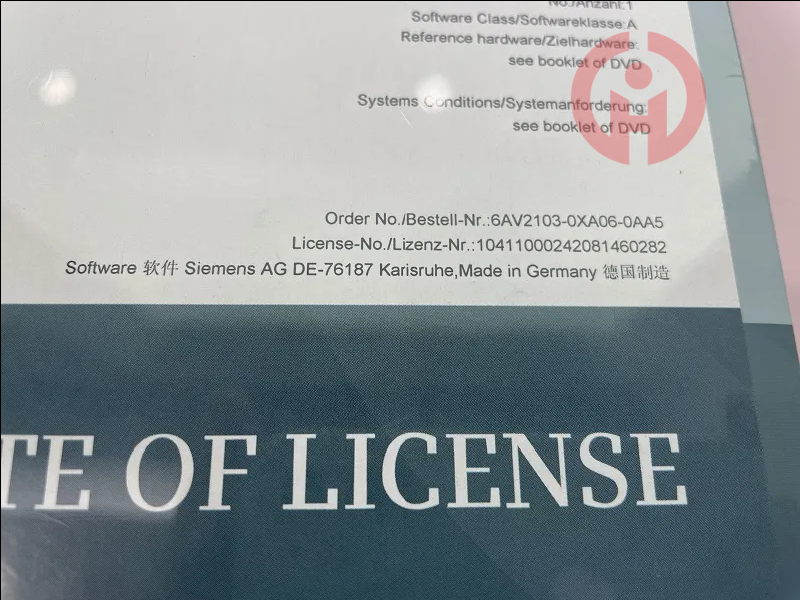

Authorization mode: Single-machine license (delivered with USB dongle), supports 1 countable client

Compatible system version: WinCC V7.4+/TIA Portal V14+

Operating system requirements: The server needs to run Windows 10 IoT Enterprise LTSC (64-bit)

Communication protocol support: PROFINET, OPC UA, Ethernet (Gigabit)

Recommended hardware configuration: Intel Core i5 and above processors, 8GB memory, 256GB SSD storage

3. Typical application scenarios

3.1 Cross-regional equipment monitoring

-- In industries such as automobile manufacturing and chemical industry, the status of equipment in multiple plant areas is centrally monitored through the Web interface, fault alarms are responded to in real time, and production processes are optimized.

3.2 Remote maintenance support

- Combine historical data and alarm logs to predict equipment failures, generate maintenance work orders and push them to the maintenance team through mobile terminals to shorten downtime.

3.3 Energy management optimization

- Integrate SCADA system, collect water/electricity/gas consumption data in real time, generate dynamic energy consumption reports, and support energy-saving and emission reduction decisions.

4. Product advantages

- Flexibility: The monitoring interface can be accessed through a browser, adapting to a variety of terminals and supporting rapid deployment.

-- High security: Hardware dongle authorization and multi-level user authority management (such as operators and engineers) are used to ensure controlled data access.

-- Scalability: Supports expansion of the number of clients through additional licenses to meet the needs of enterprise scale growth.

5. Service and support

-- Delivery content: Contains operating system software license and USB dongle, supporting rapid activation and deployment.

-- Technical support: Siemens officially provides global warranty services, covering software upgrades, debugging and technical consultation.

This product has become a core tool for remote monitoring and intelligent maintenance in industrial automation scenarios through lightweight Web architecture and industrial-grade communication protocols.

6. Technical features

-- Highly configurable: Users can highly customize it according to actual needs, whether it is the layout of the panel or the type of data registered, all can be flexibly adjusted. In addition, users can utilize its powerful scripting capabilities to program complex logic to meet changing production needs.

-- Excellent Data Processing Capability: WinCC integrates powerful database management functions that enable efficient storage and querying of historical data and support the generation of a variety of reports. By analyzing historical data, companies can identify potential production bottlenecks and make adjustments to improve overall efficiency.

-- Powerful Visualization Functions: WinCC provides a variety of visualization tools that allow users to observe and analyze the production process intuitively, whether it is charts, trend graphs, or dynamic graphics, all of which can be selected and configured according to the needs of the user, so as to easily grasp the production dynamics.

7.Application Areas

WinCC software is widely used in many industries, including but not limited to manufacturing, energy, transportation, logistics and so on. It can help enterprises realize real-time monitoring of production processes, fault alarms and data analysis, significantly improving production efficiency and equipment reliability.

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline:csyili980622@gmail.com Wechat/SKYPE:+86 13306931261