SIEMENS 6AV6362-1AF00-0BB0 SIMATIC WinCC/Web Navigator

Brand:SIEMENS

Origin:German

SIEMENS WinCC system software is an industrial automation software based on Windows Control Center (WinCC), which belongs to the HMI/SCADA software system in Siemens TIA architecture.WinCC is widely used in industrial automation field, providing WinCC is widely used in the field of industrial automation, providing an intuitive user interface and powerful monitoring functions for monitoring and controlling various industrial processes.

Product Introduction

I. Product Positioning and Core Functions

1.1 Product Positioning

-- As a Web remote monitoring solution in the field of Siemens industrial automation, it supports real-time access to the device status, process data and alarm information of the WinCC system through a browser, and is suitable for cross-regional, multi-terminal centralized monitoring scenarios.

-- Compatible with WinCC V7.4 and above and TIA Portal engineering platform, seamlessly integrated with PLC and SCADA systems, and adapted to the remote management requirements of Industry 4.0.

1.2 Core Functions

-- Real-time monitoring and data interaction: Real-time display of device operating status, process values and alarm information through the Web interface, supporting historical data backtracking and trend analysis.

-- Multi-terminal adaptation: Supports access through browsers from terminals such as PCs and tablets, without the need to install client software, reducing deployment complexity.

-- Security diagnosis and maintenance: Provides encrypted channel remote debugging of device parameters to improve maintenance efficiency.

2. Technical parameters and deployment requirements

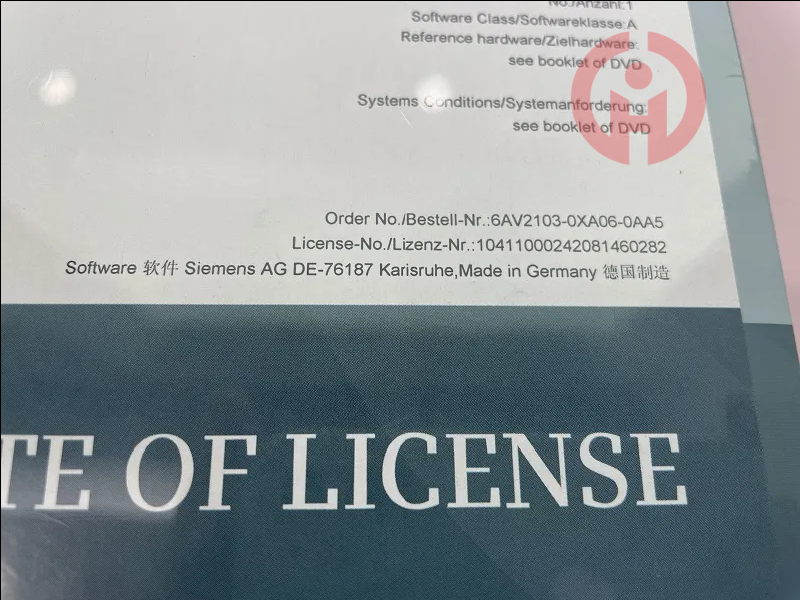

Authorization mode: Stand-alone license (delivered with USB dongle), supports 1 countable client

Compatible system versions: WinCC V7.4+/TIA Portal V14+

Operating system requirements: The server needs to run Windows 10 IoT Enterprise LTSC (64-bit)

Communication protocol support: PROFINET, Ethernet (Gigabit) and other industrial protocols

Recommended hardware configuration: Intel Core i5 and above processor, 8GB memory, 256GB SSD storage

3. Typical application scenarios

3.1 Cross-regional equipment monitoring

-- In the automotive manufacturing, chemical and other industries, the status of equipment in multiple plant areas is centrally monitored through the Web interface, and fault alarms are responded to in real time.

3.2 Remote maintenance support

-- Combine historical data and alarm logs to predict equipment failures, generate maintenance work orders and push them to the maintenance team to shorten downtime. 3.3 Energy Management Optimization

-- Integrate SCADA system to collect energy consumption data in real time and generate dynamic reports to support energy conservation and emission reduction decisions.

4. Product Advantages

Flexibility: Access the monitoring interface through a browser, adapt to a variety of terminals, and support rapid deployment.

High Security: Use hardware dongle authorization and multi-level user authority management to ensure controlled data access.

Scalability: Supports expansion of the number of clients through additional licenses to meet the needs of enterprise scale growth.

5. Basic Functions and Application Scenarios of WinCC

The core functions of WinCC include data acquisition, process monitoring, alarm management, trend analysis and report generation. It supports a variety of communication protocols, and can communicate smoothly with various types of PLCs and other automation equipment to ensure real-time data exchange.WinCC's graphical tools, such as dynamic flow charts, trend curves and operation panels, enable operators to intuitively grasp the process status and make timely and accurate operations.

6. WinCC applications in different industries

WinCC is widely used in several industries:

Manufacturing industry: Used to monitor and control production lines, mechanical equipment and processes to optimize production flow and enhance product quality and efficiency.

Energy: Real-time monitoring of power plants, transmission lines and distribution systems to ensure the stability and efficiency of energy supply.

Wastewater and water treatment: Fine monitoring of wastewater treatment plants, water treatment equipment and pipe network systems to ensure clean and safe water resources.

Building automation: Real-time monitoring and control of building power, lighting, air conditioning and security systems, providing detailed real-time data and alarm information.

Chemical and pharmaceutical industries: Strictly monitor production processes to ensure product safety and compliance.

7. WinCC's History and Competitive Advantages

Since its introduction, WinCC has rapidly become a leader in the European market and a standard to be followed in the industry due to its high level of innovation and long-term standards-based product strategy. Its openness and flexibility ensures the benefits of the user's investment.

Relationship between WinCC and other related products

WinCC is tightly integrated with SCADA systems to provide powerful monitoring and data processing capabilities for industrial automation. In addition, WinCC has a sub-product for machine-oriented automation concepts, WinCC flexible, which is used to configure user interfaces to operate and monitor machines and devices.

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline:csyili980622@gmail.com Wechat/SKYPE:+86 13306931261