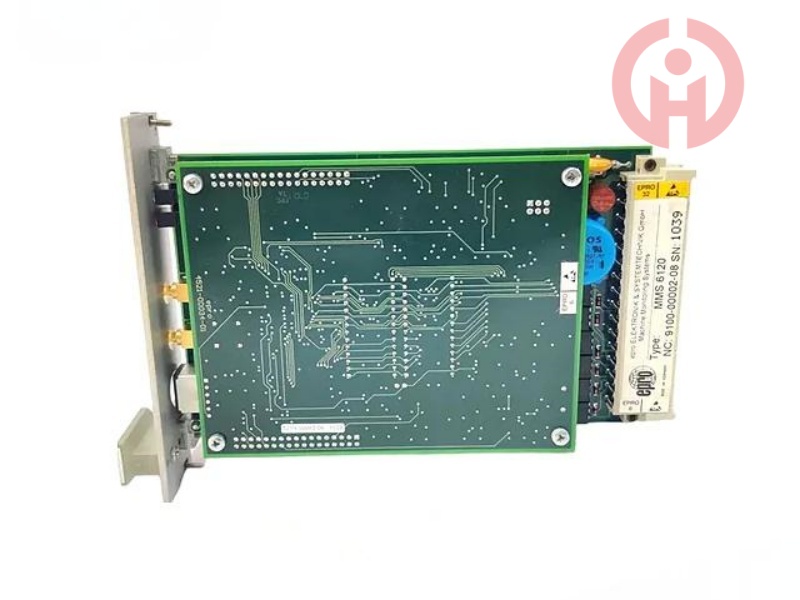

EPRO MMS6120 Dual Channel Bearing Vibration Monitor

EPRO MMS6120 Dual Channel Bearing Vibration Monitor

Origin: Germany

Brand: EPRO

We have a large amount of inventory in our warehouse. Welcome to inquire online about any model and quantity, with discounted prices.

24-hour service for you

Related products

Product Introduction

characteristic

Dual channel design: It can simultaneously monitor the bearing vibration of two channels, work independently or collaboratively, and provide comprehensive vibration data.

Can be replaced during operation: supports replacement during device operation, reduces downtime, and improves system availability and maintenance convenience.

Redundant power input: Equipped with two power inputs, it enhances the stability and reliability of the system, ensuring that it can still function normally in the event of a power failure on one of the sources.

Extended self checking function: With powerful self checking function, it can monitor the status of sensors, modules, and connecting cables in real time, detect faults such as short circuits and open circuits in a timely manner, and output the cause of the fault through the communication bus.

Password protection operation level: equipped with password protection to prevent unauthorized personnel from operating and modifying equipment parameters, ensuring the security and stability of the system.

Multiple sensor applications: Suitable for electric speed sensors PR9266/... and PR9268/... or piezoelectric sensors, with strong compatibility and can meet the needs of different application scenarios.

Powerful communication function: equipped with RS232/485 ports, it can be used for on-site configuration and communication, making it convenient for users to set working modes and parameters, read measurement values, and perform spectrum analysis through portable devices or remote communication buses.

Data recording and storage: It can record and store the measurement data of the latest start/stop, making it easy for users to analyze and trace the operating status of the equipment.

technical parameter

Sensor input: Two independent electric speed sensor inputs, electrically isolated from the power input. Input impedance>100k Ω, input voltage range -5...+15V dc. The measurement range can be continuously adjusted using configuration software, with a minimum dynamic input voltage of 311mVpp for 100% measurement range and a maximum dynamic input voltage of 9500mVpp for 100% measurement range.

Boosting coil current: The module provides independent buffered boosting coil current output for each sensor, which can be set to 0... 8mA with an accuracy of ± 0.5% of full scale/+0.5% of set value.

Control input: Two channels share binary input, which is used for channel or module prohibition. The measurement range can be expanded by factors of 1.0000... 4.9999 during start/stop. Keyphase pulse input with one pulse per revolution, used for system control, 24V logic, input impedance>10k Ω, minimum pulse duration of 10 microseconds.

Measurement mode: Each channel can be configured separately through an external portable device or communication bus, and each channel can be configured into different measurement modes to measure bearing vibration in horizontal, vertical, or axial directions, including VRMS, Sop, Spp, and other modes.

Limit detection: Each channel has two adjustable alarm values, which can be locked by the channel's normal/circuit fault function or external input. The adjustable range is 5% of the full scale... *, the resolution and repetition rate are 1 ‰ of the full scale, the alarm delay time is 1-2-3-4-5-6 seconds optional, and the switch delay is 5% of the full scale, adjustable.

output

Optocoupler output: Umax=35V dc; Imax=200mA。

Current output: Two independent 0/4... 20mA outputs, proportional to the operating mode, allowing load<500 Ω, with an accuracy of ± 1% of full scale.

Voltage output: Two independent 0...+10V outputs and two independent 0... 20Vpp outputs, proportional to the signal, load impedance>10k Ω, frequency range 0.1Hz... 5kHz (± 20%/-3dB).

application

It can be widely used for bearing vibration monitoring of various turbomachinery, fans, compressors, gearboxes, water pumps, coal mining machines and other equipment. It can effectively improve the efficiency, operational safety and prolong the service life of the equipment, meeting general standards such as API670, VDI2056, VDI2059, etc.

Many products are not yet on the shelves please contact us for more products.

If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will

arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline

csyili980622@gmail.com +86 13306931261

wujinghan102@gmail.com +8613376990653