Related products

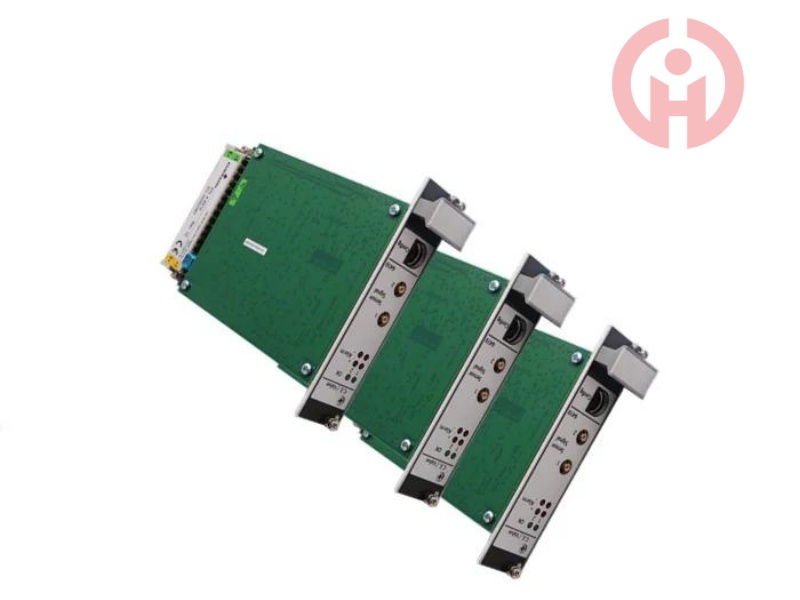

Product Introduction

technical parameter

Linear measurement range: 2mm (80mils)

Initial air gap: 0.5mm (20mils)

Incremental scaling factor (ISO): 8V/mm (203.2mV/mil) ± 5% (at 0 to 45 ° C)

Deviation from the best fitting line: ± 0.025mm (at 0 to 45 ° C)

Minimum shaft diameter: 25mm

Material of the tested object: 42CrMo4 (AISI/SAE 4140)

Protection level: IP66

Working temperature range

Sensor: -35 to+200 ° C

Cable and connector: -35 to+150 ° C

texture of material

Sensor probe: PEEK

Shell: Stainless steel

Cable: PTFE

Connector: Nickel plated brass

Weight: Approximately 100 grams (sensor with 1-meter cable)

Thread specification: M10x1 or 3/8-24UNF

Wrench size: SW8mm (M10 thread), WS5/16 inch (3/8-24UNF thread)

Cable diameter

Standard: 2.8mm

Armor: 6mm

Product Features

Non contact measurement: Based on the eddy current effect, it does not require contact with the object being measured, avoiding wear on the surface of the object and not interfering with its motion state. It can be accurately measured without affecting the object being measured.

High precision and high reliability: With high linearity and resolution, it can accurately detect small displacement changes and provide accurate data for equipment status monitoring; Made with high-quality materials and advanced technology, it can work stably in harsh industrial environments, has strong anti-interference ability, and reduces measurement errors and data fluctuations.

Fast response speed: It can quickly track the dynamic changes of the measured object, output measurement signals in a timely manner, accurately capture the instantaneous state changes of the measured object, and is suitable for measuring objects that rotate or vibrate at high speeds.

Compliant with international standards: The manufacturing and use comply with various international universal standards such as DIN 45670, ISO 10817-1, and API 670, making it easy to apply in industrial projects in different countries and regions, and ensuring compatibility with other standard compliant equipment and systems.

Explosion proof performance: Complies with relevant explosion-proof standards such as ATEX, IEC Ex, CSA, etc., and can be used in hazardous areas with explosion-proof requirements.

application area

Mainly used for condition monitoring of key turbomachinery equipment such as steam, gas, and hydro turbines, compressors, pumps, blowers, and fans. It can be used to measure parameters such as radial and axial displacement, vibration, eccentricity, shaft bending, bearing wear, oil film thickness, relative thermal expansion between shaft and bearing, thermal expansion of bearing, and valve position of rotating shaft, thereby achieving real-time monitoring and fault diagnosis of equipment operation status and ensuring safe and stable operation of equipment.

In which application scenarios does reverse installation of eddy current sensors have more advantages? What is the price of EPRO PR6423-00R-010 eddy current sensor? Recommend some products that can replace EPRO PR6423-00R-010

Many products are not yet on the shelves please contact us for more products.

If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will

arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline

csyili980622@gmail.com +86 13306931261

wujinghan102@gmail.com +8613376990653