SIEMENS 7MB2337-0NH00-3PN1 INFRARED GAS ANALYZER

Brand:SIEMENS

Origin:German

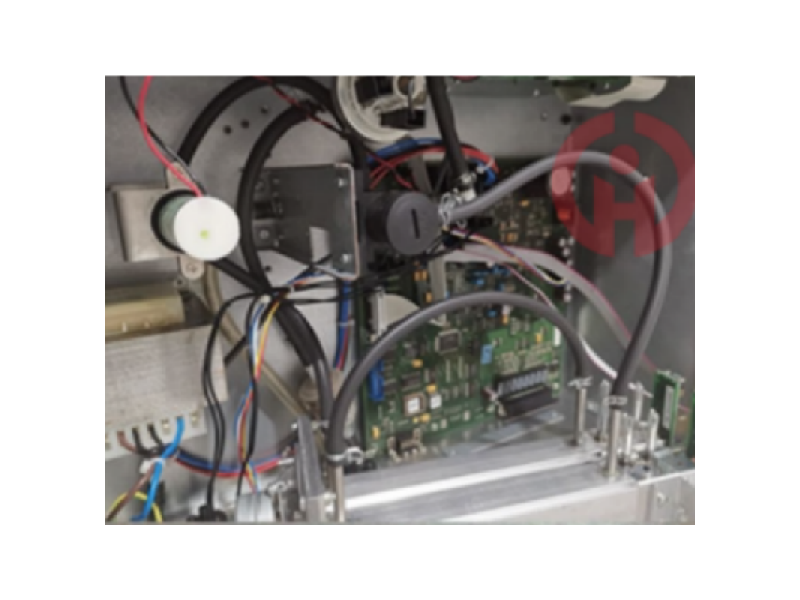

The Siemens 7MB2337-0NH00-3PN1 infrared gas analyzer is a high-performance gas analyzer primarily used for gas monitoring and control in industrial processes. This analyzer is based on the principle of selective absorption of infrared light by the sample medium and measures the concentration of the sample gas by measuring the infrared radiation intensity after it passes through the gas.

Related products

Product Introduction

1. Siemens infrared gas analyzers (such as Ultramat 23 series) use non-dispersive infrared technology (NDIR), which is specially designed for industrial gas concentration measurement and suitable for continuous monitoring of multiple gases (such as CO, CO₂, CH₄, SO₂, etc.), with high precision, strong anti-interference and good long-term stability.

2. Typical application scenarios

-- Industrial process control: gas concentration monitoring in chemical, petrochemical and power industries.

-- Environmental emission monitoring: flue gas emissions (such as NOx, SO₂), greenhouse gas detection.

-- Safety protection: flammable or toxic gas leakage alarm.

-- Laboratory analysis: gas purity or mixing ratio detection.

3. Technical Parameters

Measuring principle: Non-dispersive infrared (NDIR)

Measuring range: Customized according to gas type (e.g. CO: 0-1000 ppm, CO₂: 0-20% vol)

Accuracy: ±1% full scale (FS)

Response time: ≤10 seconds (T90)

Output signal: 4-20 mA, RS-232/RS-485, Ethernet (optional)

Ambient temperature: -5°C to +45°C (operating temperature)

Protection level: IP65 (dustproof and waterproof)

Power supply: 100-240 V AC, 50/60 Hz

4. Product Features

4.1 High reliability

- Anti-vibration and corrosion-resistant design, suitable for harsh industrial environments.

4.2 Modular structure

- Supports expansion of multi-gas measurement modules.

4.3 Intelligent diagnosis

-- Self-check function, fault alarm and historical data storage.

4.4 Low maintenance cost

-- Long-life infrared light source and gold-plated gas chamber to reduce calibration frequency.

-- High monitoring sensitivity: High monitoring sensitivity, can distinguish small changes in gas concentration.

-- High measurement accuracy: Generally in FS (full scale), compared with other analysis methods, it has higher accuracy and good stability.

-- Fast response speed: The response time is generally within 10S (time reaches T90).

-- Low maintenance cost: With air self-calibration function, high efficiency does not require calibration gas and accessories, and is almost maintenance-free. Multi-layer detection -- ensures high accuracy and small lateral sensitivity. The sampling unit is easy to clean, reducing maintenance costs.

-- Easy operation: With menu-assisted operation in simple text format, it can be operated and controlled without manual, which is very safe.

-- Good data integration: open interface structure (RS485, RS232, PROFIBUS, SIPROMGA), simplified process integration, remote control, data can be imported into other systems.

5. Precautions for use

-- Installation environment: Avoid strong electromagnetic interference or drastic temperature fluctuations.

-- Calibration cycle: It is recommended to calibrate the standard gas every 6-12 months.

-- Gas path treatment: Filters and dehumidification devices are required to prevent probe contamination.

· Many products are not yet on the shelves please contact us for more products.

· If there is inconsistency between the product model and the display picture, the model shall prevail, please contact us for specific product pictures, we will arrange to take pictures in the warehouse to confirm!

Technical Team Service Hotline:csyili980622@gmail.com Wechat/SKYPE:+86 13306931261